16/01/2024

Chain sharpening made easy!

Source: landwirt.com

During the weeks of intensive timber harvesting, it's important to regularly maintain your chainsaw chain. Proper sharpening keeps the chain ready for use and extends its lifespan.

Working with a chainsaw that you only have to guide as it pulls itself into the wood and cuts is pleasant and motivating. Especially during the strenuous task of harvesting timber, forest owners are grateful for tools that make their work easier. However, if the tool is to function well, it must also be maintained regularly. This is especially true for the chainsaw chain. The cutting assembly, consisting of the chain drive wheel, guide bar and saw chain, converts the engine's power into cutting performance. Even with constant engine power, however, the cutting performance decreases due to wear or damage to the cutting edge, and the chain must be repaired. If you want to maintain the chain optimally, there are just a few points to consider.

Advantages of an optimally repaired chain

- Reduced risk of accidents and fatigue

- Reduction of kickback and vibration

- performance improvement

- Less material wear and fuel consumption

How often should you sharpen?

There's no rule of thumb for how often you should sharpen your chain. Chain sharpness depends on many different factors, such as weather conditions (frost), the type of wood, and the age of the chain. If you notice the following, it's time to sharpen the chain.

- The chain no longer pulls into the wood by itself and you have to help it by applying pressure to the chainsaw

- When cutting to length, the saw no longer produces coarse chips but fine sawdust

- Although the chain is intact, lubricated and tensioned, the chainsaw smokes

- If the incisors are not of equal length or blunt on one side, the cut only runs in one direction

The incisor

The tooth roof forms the tooth length. It gets lower from front to back. The cut will only be straight and even if the left and right rows of teeth are the same length and height. If the rows of teeth are unequal lengths, the higher row of teeth will engage the wood more. This leads to a crooked cut. The main cutting edge forms the front end of the tooth roof. This is also where the incisor is subjected to the greatest strain. The sharpening angle of the main cutting edge is between 25 and 35 degrees, depending on the type and condition of the wood. The secondary cutting edge is the beginning of the tooth face and is partly responsible for chip separation. The depth gauge determines the working depth. The difference in height between the main cutting edge and the depth gauge is removed as chip. This difference must never be too large!

What tooth shape?

When purchasing a saw chain, you have the choice between two different tooth shapes: the chisel tooth and the semi-chisel tooth. The chisel tooth is more suitable for professional use due to its somewhat more complicated maintenance.

The semi-chisel tooth is very easy to sharpen and holds the edge well. Users who aren't familiar with filing should therefore purchase a chain that doesn't have square cutting teeth.

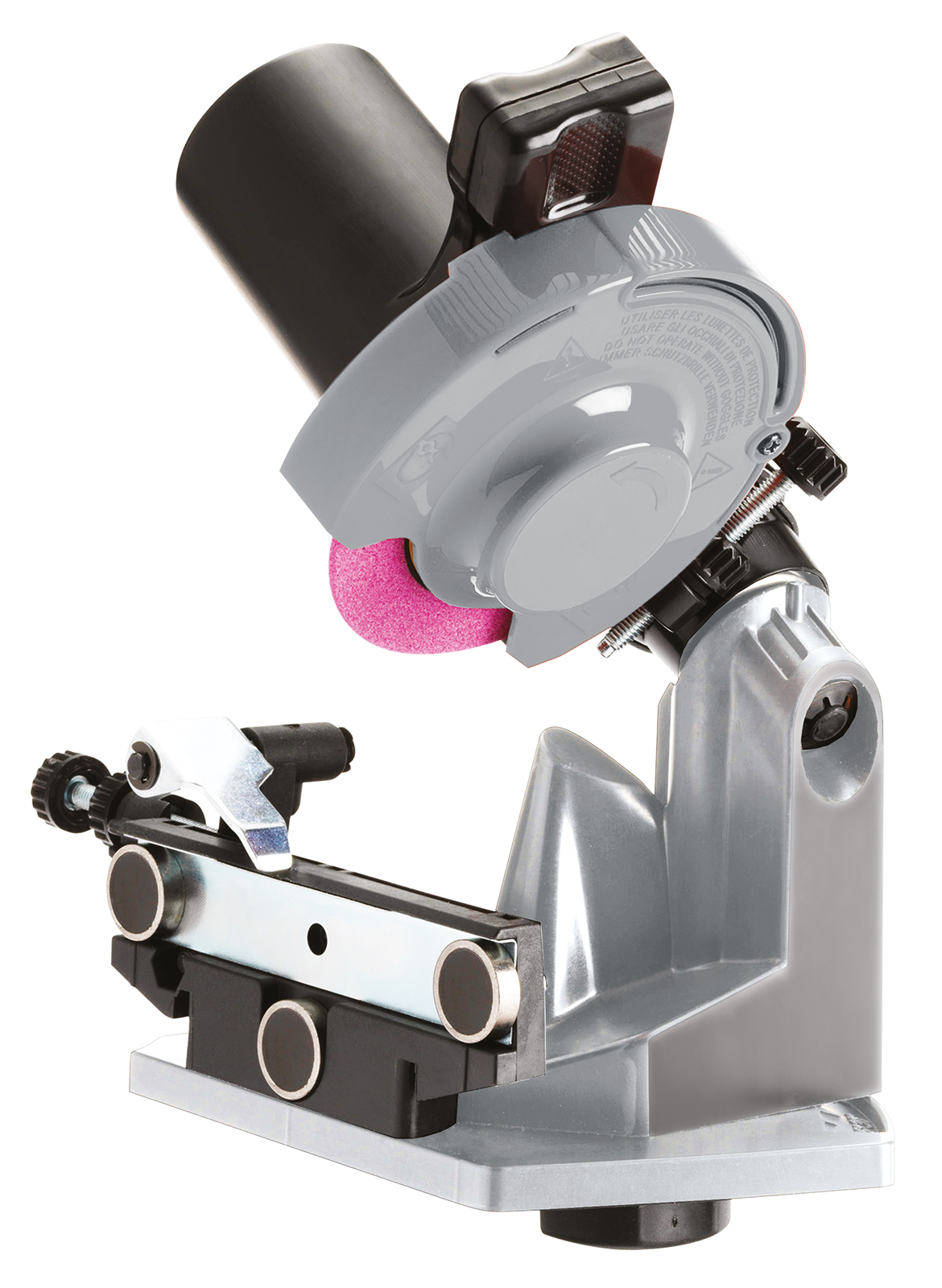

Sharpening or grinding

- Round file according to the chain pitch and tooth height

- File handle

- Sharpening grid

- Depth gauge

- flat file

The work steps:

1. Checking the chain tension

2. Clamping the chainsaw

If it's necessary to file the chain during harvesting, it can also be clamped to a stick or tree stump. Be sure to check the chain tension before sharpening.

3. Assessment of tooth length

All incisors should appear approximately the same length. If they aren't, the cut will be uneven.

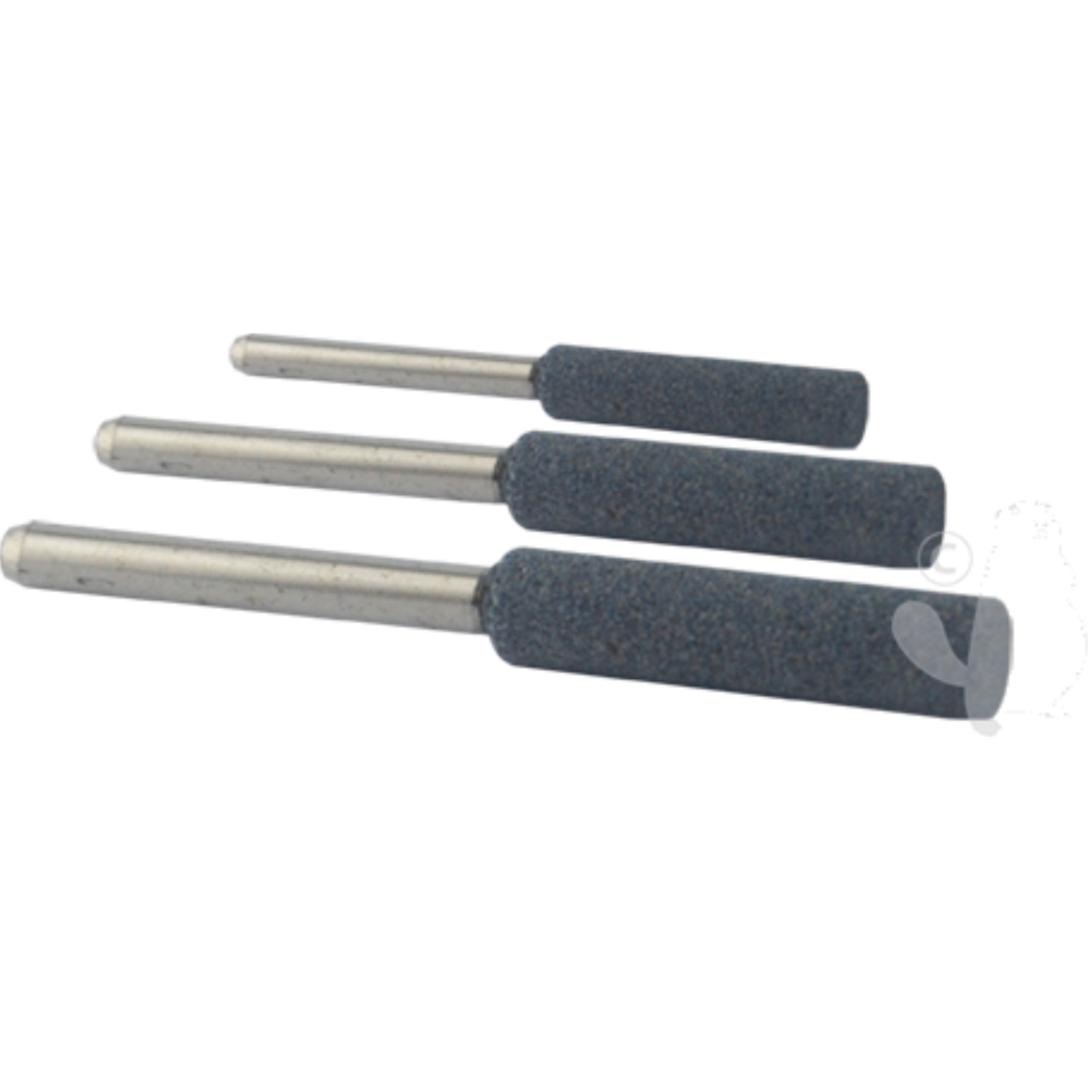

4. Choosing the right file according to the chain pitch

Eleven rivets each make up the chain pitch. Measure from rivet center to rivet center. The round file used should extend 1/5 to 1/10 of the diameter above the tooth crown. This ensures the appropriate stability of the crown cutting edge and thus extends the service life. The tooth height varies depending on the chain pitch, so different file diameters are used depending on the pitch: The 3/8 low-profile chain is primarily found on hobby saws and chainsaws for tree care. Once about half of the cutting tooth has been filed away, switch from the larger to the smaller round file according to the table.

5. Sharpening angle of the main cutting edge

An angle of 35 degrees is used for unfrozen softwood; for hardwood and frozen softwood, an angle between 25 and 30 degrees is chosen. The larger sharpening angle results in more power for unfrozen softwood. A smaller sharpening angle results in smoother operation and less vibration for frozen wood and hardwood. To ensure you achieve the correct angle for each cutting tooth, we recommend using a sharpening grid. The cutting teeth are coated (tempered) with a hard chrome layer. This is significantly harder than the file. Therefore, file from the inside of the tooth to the outside.

6. File guide

Guide the round file with both hands. With a half-chisel tooth, guide the file parallel to the tooth crown. The file must be flush with the main cutting edge. This means there must be no gap between the round file and the main cutting edge! With a chisel tooth, however (especially with the 3/8-inch chain pitch), the file is pulled through at a ten-degree angle from bottom to top and with a sharpening angle five degrees wider than the main cutting edge. The goal of uphill filing is to achieve the most stable point possible where the main and secondary cutting edges meet (see tooth shape diagram).

The file and forearm should be guided in as straight a line as possible. The thumb at the front end of the file should not rest on the top, but should press the file laterally into the incisor.

When filing, never file a connecting link or drive link! Guide the file with moderate pressure! If a file no longer grips, replace it immediately. Right-handed people usually sharpen the right incisors first, then the left incisors by turning the chainsaw or changing location. For a more even and better result, the right incisors should be filed with the right hand and the left incisors with the left hand. When filing, the round file is pressed into the incisor using its entire length and with moderate pressure, making sure that it is flush with the tooth roof (main cutting edge). Turning the file is not necessary. The tooth is sharpened when there is no longer any damage to the hard chrome layer on the main cutting edge or when a continuous burr is visible. During the filing process, the secondary cutting edge should also always be taken into account to prevent any "overhang". The optimal secondary cutting edge is approximately five degrees for the semi-chisel tooth and ten to 15 degrees for the chisel tooth.

Possible causes of snagging include using the wrong file (too small) or filing too deeply. The disadvantage of snagging is that the crown edge is too thin. This significantly shortens the lifespan of the edge. A file that is too large or excessive upward filing causes snagging. The crown edge becomes more stable, but cutting performance decreases. The principle "frequent filing results in fewer filing errors and better performance" should be followed.

7. Checking the depth limiters

After sharpening approximately three to five times, check the depth gauge of the cutting tooth using a suitable gauge and flat file. A depth gauge that's too low increases the risk of kickback and vibration, and the chain will jam while cutting. Depending on the chainsaw thickness, wood type, and wood condition, the depth gauge should be lowered by approximately 0.6 to 0.8 mm.

Frozen wood should be treated like hardwood. If the depth gauges are filed down horizontally, they should be rounded or chamfered if necessary. Their new shape should be retained.

You can find all products on this topic here: Chain sharpening, riveting tools!