23/04/2024

Cheese production

Introduction

Cheese making is a fascinating art. In this comprehensive guide, you will learn step by step how to make delicious cheese at home, from selecting the ingredients to maturing.

Ingredients

Milk: Ideally, high-quality milk should be used. Fresh, unpasteurised milk is best. Alternatively, pasteurised milk can also be used as long as it has not been ultra-heated.

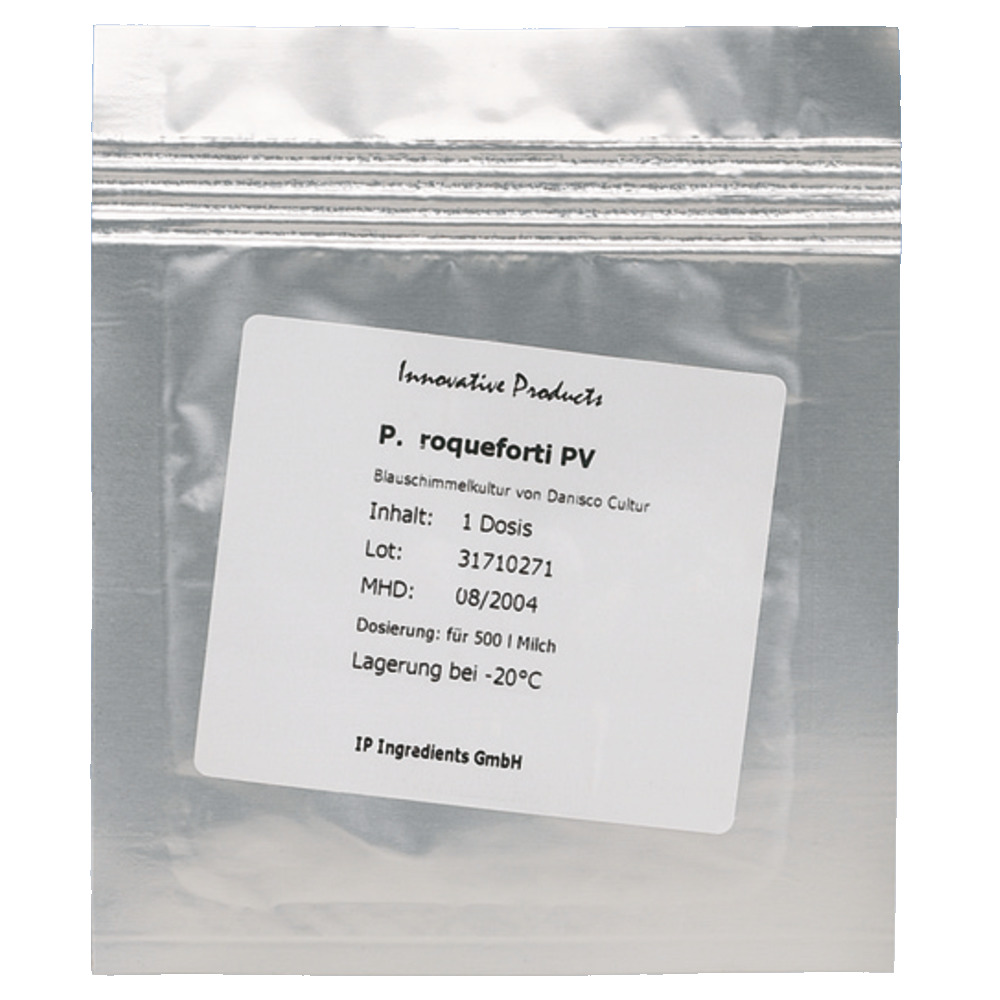

Cheese cultures: These are microorganisms that give the milk flavour and texture during the fermentation process. They can be purchased in powder or liquid form.

Rennet: Rennet is an enzyme that coagulates milk and gives it a firm texture. Rennet is available in liquid or powder form and is added to the milk during the curdling process.

Salt: It is important not to use iodised salt, as iodised salt can impair the fermentation process.

Pot: A large stainless steel or enamelled pot is used to heat the milk.

Thermometer: Precise temperature control is crucial for the quality of the cheese.

Sieve: A fine sieve is needed to separate the curdled milk from the whey.

Steps for cheese production

Preparing the milk: Pour the milk into a pan and slowly heat it to the required temperature according to your recipe. This temperature varies depending on the type of cheese and recipe, but is typically between 30°C and 40°C.

Adding cultures and rennet: Once the milk has reached the right temperature, add the cheese cultures according to the instructions in your recipe. Stir thoroughly to ensure that the cultures are evenly distributed. Then add the rennet and stir it in gently too. These steps activate the fermentation process and curdle the milk.

Allow to curdle: Cover the pan and leave the milk to rest until it curdles. The duration of this step varies depending on the type of cheese and temperature. During the curdling process, the milk should take on a pudding-like consistency and develop a firm texture.

Cutting and separating the whey: After the milk has curdled, cut the curd into small cubes to release the whey. Then leave the curdled mass to rest so that the whey can settle. The whey is then carefully poured off or skimmed off, depending on the type of cheese and recipe.

Pressing and moulding: The curdled mass is placed in cheese moulds. The cheese is then pressed to remove excess whey and achieve a firm texture. The duration and pressure of pressing vary depending on the recipe and cheese type.

Salting and maturing: After pressing, the cheese is removed from the mould and salted to taste. The salt is rubbed evenly onto the surface of the cheese. The cheese is then stored in a cool, dry place to mature. The maturing time varies depending on the type of cheese and can last from a few days to several months. During the ripening process, the cheese is regularly turned and handled to ensure even development of flavour and texture.

Tips and tricks

Hygiene: Keep your working environment and equipment clean throughout the process to avoid contamination. Sterilise your equipment before use and wash your hands thoroughly to ensure safe cheesemaking.

Storage: After ripening, it is important to keep the cheese in a cool, damp room to ensure optimum ripening. Use airtight containers or cheese bells to protect the cheese from drying out and foreign odours.

Control the temperature and pH: Accurate control of the temperature and pH during the production process is crucial for the quality of the cheese. Use an accurate thermometer and pH meter to ensure that conditions are optimal.

Maintain the ripening process: During the ripening process, it is important to turn the cheese regularly and maintain its surface to achieve even ripening and prevent the formation of unwanted mould. Check your ripening room regularly and adjust the conditions if necessary.

Different types of cheese and how they are made

Cream cheese: is easy to make and does not require maturing. After the milk has curdled, the cheese is lightly pressed and flavoured with salt.

Soft cheeses: such as Camembert or mozzarella, require a short maturing period. After curdling and pressing, the cheese is rubbed in salt and then matured in a cool room. During this maturing process, the cheese develops a characteristic white mould on its surface.

Hard cheeses: such as Cheddar or Gouda, require a longer maturing time and higher pressure when pressed. The cheese is rubbed in salt and then matured for weeks or even months in a cool room.

Blue cheeses: such as Roquefort or Stilton, are produced by introducing mould cultures during the manufacturing process. The cheese is pierced with needles to let in air, which encourages mould growth. It is then matured in a cool, damp room.

White mould cheese: like Brie or Camembert, this is produced in a similar way to soft cheese, but with an additional layer of noble mould (Penicillium candidum or Penicillium camemberti) on the surface. After curdling and pressing, the cheese is rubbed in salt and then matured. During the ripening process, the cheese develops a velvety white mould coating on the surface.

Mistakes

Curdling too quickly: If the milk curdles too quickly, this may be due to too high a temperature or an excessive addition of rennet. To avoid this, it is important to heat the milk slowly and dose the rennet precisely.

Storage

Storage: Once the cheese has matured, keep it in a cool, damp room to ensure optimum ripening. Use airtight containers or cheese bells to protect the cheese from drying out and foreign odours.

Maturation and affinage

Cheese cellar: A cheese cellar provides optimum conditions for maturing cheese, including a constant temperature and humidity. Ideally, the temperature should be between 10°C and 14°C, while the humidity should be kept at around 80-90%. These conditions promote the development of complex flavours and textures in the cheese during ripening.

Recognising and eliminating cheese defects

Mould growth: Mould growth on the surface of the cheese may be due to insufficient ventilation or high humidity. If mould is detected, carefully remove it with a clean knife and check your ripening environment for optimal conditions. Make sure that the cheese is sufficiently ventilated and that the humidity is not too high to prevent future mould growth.